- All Products

- Trailers & Skid Units

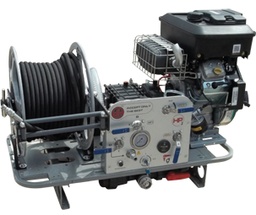

- Wildland CET High Pressure Skid Unit w/ 200 Gallon Tank & Foam System - Estimate showing, price available on request

Wildland CET High Pressure Skid Unit w/ 200 Gallon Tank & Foam System - Estimate showing, price available on request

Freight and crating is extra

Pumps

Wildland CET High Pressure Skid Unit – Versatile, High-Performance Fire Suppression 🚒

The Wildland CET High Pressure Skid Unit is a powerful, modular firefighting solution designed for efficient water and foam application in wildland and interface fire scenarios. Built to tackle tough environments, this unit combines high-pressure performance with portability, making it an indispensable tool for rapid response teams.

Key Features:

- High-Pressure Pumping:

- Equipped with a CET piston-type high-pressure pump delivering 11 GPM at a formidable 1450 PSI, ensuring effective suppression with minimal water usage.

- Self-priming design enhances operational readiness and ease of use, reducing setup time in critical situations.

- Robust Engine:

- Powered by a 16hp Briggs and Stratton engine with an integrated gas tank for reliable and consistent performance in the field.

- Includes a 1.5-gallon fuel tank, providing ample runtime for extended operations.

- Foam System:

- Integrated high-pressure foam proportioning system for consistent foam application across a range of concentrations, enhancing fire knockdown efficiency and resource conservation.

- Flexible Discharge Options:

- Triple-use discharge gun capable of fog, jet, and atomized spray modes for versatility in various fire conditions and tactical needs.

- Durable Construction:

- High-strength epoxy-treated frame for exceptional durability and rust resistance, ensuring longevity and reliability in harsh environments.

- Comprehensive Hose Setup:

- Includes an electric hose reel with 150 feet of high-pressure hose for extended reach and maneuverability.

- Auxiliary outlet on the control panel allows for the connection of a second line, expanding operational flexibility.

- Modular Design:

- Custom pump panel and modular configuration allow for easy integration and adaptability to specific operational requirements.

- Available with polypropylene water tanks ranging from 50 to 500 gallons, with this unit featuring a 200-gallon tank for balanced capacity and mobility.

Specifications:

- Engine: 16hp Briggs and Stratton

- Pump: CET Piston Type

- Flow Rate: 11 GPM

- Pressure: 1450 PSI

- Tank Capacity: 200 Gallons (Polypropylene)

- Hose Length: 150 feet

- Price: CND 32,260.73 (Freight and crating extra)

Actionable Tips:

- Foam Management: Regularly check and calibrate the foam proportioning system to ensure optimal performance.

- Maintenance: Perform routine maintenance on the engine and pump to prevent downtime and extend the unit's lifespan.

- Training: Ensure personnel are trained on operating the skid unit, focusing on the foam system and discharge gun for effective use in varied conditions.

Alternative Perspectives:

- Water-Only Options: For areas with abundant water supply, a water-only skid might suffice, but foam systems offer superior fire suppression and can be crucial in water-scarce environments.

- Customization: Depending on your operational needs, consider customizing the configuration to include additional accessories or different tank sizes.

Setup and Operation Guide for Wildland CET High Pressure Skid Unit 🚒

Preparation:

- Inspect the Unit:

- Check the engine oil level and fuel tank. Ensure the tank is filled with the appropriate fuel (gasoline for Briggs and Stratton engines).

- Inspect hoses, connections, and the foam proportioning system for any signs of wear or damage.

- Review Safety Protocols:

- Ensure all operators are wearing appropriate personal protective equipment (PPE).

- Familiarize yourself with the engine and pump controls, as well as emergency shut-off procedures.

Setup:

- Position the Unit:

- Place the skid unit in a stable location, ensuring it’s on a level surface to prevent tipping during operation.

- Ensure the unit is accessible for refueling and maintenance but away from direct fire exposure if possible.

- Connect Hoses:

- Attach the high-pressure hose to the discharge outlet using the provided connections.

- Secure the suction hose to the inlet, ensuring the poly foot strainer is submerged in water if drawing from an external source.

- Prepare the Foam System:

- Check the foam concentrate level in the integrated tank.

- Set the foam proportioning system to the desired concentration using the control knob, based on the firefighting requirements.

Operation:

- Start the Engine:

- Follow the engine start-up procedure: turn the fuel valve to "ON," set the choke (if necessary), and pull the starter cord or engage the electric start, if equipped.

- Allow the engine to warm up for a few minutes before engaging the pump.

- Engage the Pump:

- Gradually open the discharge valve while monitoring the pressure gauge to ensure it reaches the desired operating pressure (1450 PSI).

- Adjust the throttle to stabilize the pressure, using the automatic acceleration system to maintain consistent performance.

- Apply Foam or Water:

- Use the triple-use discharge gun to apply foam or water as needed. Adjust the spray pattern (fog, jet, atomized) based on tactical needs.

- Monitor the foam application and adjust the proportioning settings if necessary for optimal coverage and suppression.

Post-Operation:

- Shutdown:

- Gradually close the discharge valve and throttle back the engine to idle.

- Turn off the engine and close the fuel valve.

- Maintenance:

- Drain any remaining water from the tank and hoses to prevent freezing or contamination.

- Clean the unit, focusing on the pump, hoses, and foam system to prevent buildup or corrosion.

- Check and refill any fluids (engine oil, foam concentrate) as needed for the next operation.

Actionable Tips:

- Regularly test the foam system with water to ensure proper function without wasting foam concentrate.

- Keep a log of maintenance activities and any issues encountered to ensure ongoing reliability and performance.

Alternative Perspectives:

- Some users may prefer manual hose reels for simplicity and reduced maintenance, but electric reels offer convenience, especially for frequent deployments.

- Consider pairing the skid unit with additional water storage solutions for extended operations in remote areas.

Foam Concentrate Types and Applications 🌊

1. Class A Foam:

- Description: Designed for wildland and structural fire suppression, Class A foam enhances water penetration and wetting ability, making it ideal for vegetative fuels and building materials.

- Application: Use in wildland firefighting, structural firefighting, and overhaul operations to suppress fire and prevent rekindling.

- Concentration: Typically applied at 0.1% to 1% depending on the scenario and material involved.

2. Class B Foam:

- Description: Used for flammable liquid fires (fuel, oil, etc.), Class B foam forms a film over the liquid surface to suppress vapors and extinguish the fire.

- Application: Effective in industrial settings, fuel depots, and any scenario involving liquid fuel spills.

- Concentration: Usually applied at 3% to 6%, depending on the fuel type and situation.

3. AFFF (Aqueous Film Forming Foam):

- Description: A subtype of Class B, AFFF spreads rapidly across flammable liquid surfaces to form a thin aqueous film, providing quick knockdown.

- Application: Commonly used at airports, refineries, and similar environments where rapid suppression of flammable liquid fires is critical.

- Concentration: Generally used at 3% to 6%.

4. Alcohol-Resistant AFFF:

- Description: This foam is specifically formulated to handle polar solvents (alcohols, ketones) that can break down standard AFFF.

- Application: Ideal for chemical plants and storage facilities where polar solvents are present.

- Concentration: Used at 3% to 6%, with specific instructions based on the foam manufacturer.

Actionable Tips:

- Select the Right Foam: Match the foam type to your operational needs and the most likely fire scenarios you might encounter.

- Regular Testing: Periodically test your foam system with water to ensure it's functional and calibrated without wasting foam concentrate.

- Foam Storage: Store foam concentrates in a cool, dry place to maintain their effectiveness and shelf life.

Alternative Perspectives:

- Some departments may prefer to stock multiple types of foam to cover a wider range of incidents, but this requires careful management of stock and training.

- Environmental considerations are also important; some foams have environmental impacts, so choosing biodegradable or environmentally friendly options can be beneficial.

![[710001527] Wildland CET Econo Pac Bush Buggy Package - Estimate showing, price available on request](https://cdn.wfrfire.com/web/image/product.template/450/image_512/%5B710001527%5D%20Wildland%20CET%20Econo%20Pac%20Bush%20Buggy%20Package%C2%A0-%20Estimate%20showing%2C%20price%20available%20on%20request?unique=3d8cb78)

![[710001147] Wildland CET Forest Pac Bush Buggy Package - Estimate showing, price available on request](https://cdn.wfrfire.com/web/image/product.template/451/image_512/%5B710001147%5D%20Wildland%20CET%20Forest%20Pac%20Bush%20Buggy%20Package%C2%A0-%20Estimate%20showing%2C%20price%20available%20on%20request?unique=3d8cb78)

![[710001526] Wildland CET Ready Pac Bush Buggy Package - price available on request](https://cdn.wfrfire.com/web/image/product.template/452/image_512/%5B710001526%5D%20Wildland%20CET%20Ready%20Pac%20Bush%20Buggy%20Package%20-%20price%20available%20on%20request?unique=3d8cb78)

![[710001037] Wildland CET Skeeter Space Pac Bush Buggy Package -- Estimate showing, price available on request](https://cdn.wfrfire.com/web/image/product.template/453/image_512/%5B710001037%5D%20Wildland%20CET%20Skeeter%20Space%20Pac%20Bush%20Buggy%20Package%20--%20Estimate%20showing%2C%20price%20available%20on%20request?unique=3d8cb78)